2021-10-31 Views:8703

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

Many gold concentrators are now striving to achieve green mines. This article introduces an eco-friendly gold stripping powder, which can replace cyanide to complete gold leaching. Not only is the leaching efficiency high and the production cost low, but more importantly, it can help the gold concentrators achieve the goal of creating a green mine. This article will give a brief introduction to three aspects of why environment-friendly gold extracting agent appearing, how to prepare it and how to extract gold using the new gold leaching chemical.

When using the cyanide process to extract gold, sodium cyanide is the most commonly used gold extraction agent. But as a gold leaching agent, sodium cyanide has the following disadvantages:

(1) When sodium cyanide is used as a gold extraction agent for cyanide gold separation, the stirring and leaching cycle of gold ore is 24 to 72 hours, and the heap leaching cycle is 1 week to 1 year. The gold extraction cycle is longer and the work efficiency is low;

(2) Impurities, like organic carbon, antimony, arsenic, copper, and zinc in gold ore, are easy to consume sodium cyanide first, which reduces the concentration of sodium cyanide in the solution, and finally the dissolution rate of gold ore is reduced, and the leaching efficiency is reduced. A higher concentration of sodium cyanide solution is needed, which increases the production cost.

(3) The product getting from the reaction of NaCN and gold ore is highly toxic and pollutes the environment. Many countries have explicitly banned the use of sodium cyanide to leach gold.

In view of the shortcomings in the existing technology, after unremitting exploration and experimentation, the beneficiation experts invented an environmentally friendly gold stripping power. The use of the eco-friendly gold extractor can shorten the heap leaching cycle, speed up leaching rate, improve work efficiency, and not only reduce production cost, but also achieve the purpose of environmental protection. You may be more curious here, what are its ingredients? Let us continue to introduce to you.

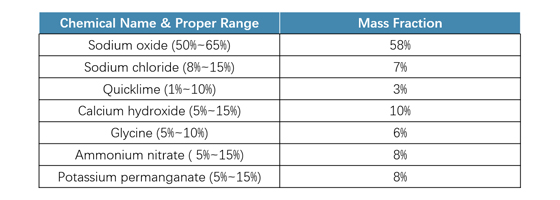

First of all, the preparation method of the gold dressing agent is: mixing dry sodium oxide, sodium chloride, quicklime, calcium hydroxide, glycine, ammonium nitrate, and potassium permanganate powders uniformly and sealing them. The dosage of various agents is shown in the table below:

(proportion of each component in preparation of gold stripping powder)

After the preparation of the eco-friendly gold stripping agent is completed, the specific steps for extracting gold using it are as follows:

Step1 The sample of gold ore is impurity removed and crushed to a fineness of 80% 200 mesh to obtain gold ore powder.

Step2 According to the quality of the gold ore powder from 0.01% to 0.05%, weigh the eco-friendly gold stripping powder;

Step3 The eco-friendly gold stripping powder is added to pure water to configure a gold leaching agent syrup with a mass concentration of 0.1% to 0.18% and a pH value of 10 to 12.

Step4 Add the gold ore powder to the prepared eco-friendly gold stripping agent to obtain a slurry. Under the conditions of a stirring speed of 250~300r/min and a temperature of 10°C, adjust the slurry to a concentration of 40%~50% and a pH value of 10~12.

Step5 Put the pulp into the leaching tank, leaching for 6~15h at a stirring speed of 200~250r/min and a ventilation speed of 130~150m 3/h to obtain an leaching rate of 98. 7%~99. 3% gold slurry.

Step6 Under the condition of stirring speed 200~250r/min, put activated carbon into the precious liquid at a concentration of 10~15g/L to adsorb gold, the adsorption time is 6~12h, and the gold-loaded carbon with an adsorption rate of 91%~98% is obtained. .

Step7 After separating the gold-loaded carbon from the slurry, put it into an electrolytic cell with steel wool as the cathode, and desorb it for 24 to 36h under the conditions of a temperature of 95°C, a voltage of 3~3.5V, and a current density of ΙΟΑ/m2 to obtain Gold-containing steel wool has a desorption rate of 90% to 96%.

Step8 The gold-containing steel wool is added to the reducing agent to perform the reduction reaction. The reaction temperature is 15~30°C, the reaction time is about 30 minutes, and the reduction rate of the reduction reaction is 95.2%~99% to obtain gold powder. Then melt it to get gold bullion. Finally, the total recovery rate of gold is 89.4%~97. 8%.

These are the steps of using eco-friendly gold stripping powder to extract gold.

Through the introduction of the preparation method and gold extraction method of the eco-friendly gold stripping power, you can know three advantages of it:

However, due to the different nature of the gold mine, the leaching effect of the eco-friendly gold stripping powder may be different. It is recommended that you first use a sample of the eco-friendly gold stripping power to conduct an leaching test to determine whether it is suitable for your gold mine.

+8618890227893

+8618890227893

pinklaurabao@gmail.com

pinklaurabao@gmail.com

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

TOP