CNFREE eco-friendly gold leaching reagent is a kind of leaching reagent that can replace sodium cyanide without changing the original equipment and cyanide process. It can be used directly for gold ore beneficiation and refining. Compared with the traditional leaching agent, it can truly achieve targets of green and environmental protection with no severe accidents.

100% replacement of sodium cyanide; 100% environmental protection; no need to change the original cyanidation process and gold extraction equipment; suitable for various cyanide gold extraction processes; widely applied to various gold mines.

Oxidized ore of gold and silver , primary ore, sulphide ore, electronic waste, cyanide tailings, the heap of gold concentrate , pool leaching, CIP (agitation leaching) process.

1. High-tech products: It is the world's first high-tech products to replace sodium cyanide for gold beneficiation.

2. Low toxicity and environmental protection: the product is non-combustible, non-explosive, non-oxidant risk, non-radioactive, low-toxic,belongs to ordinary chemical product with environmentally safe.

3. Stable performance: it can reduce the interference of harmful substances such as arsenic and sulfur.

4. Strong applicability: it is suitable for heap leaching, pool leaching and CIP process of oxidized gold and silver ore. The scale can be large or small, and it is more suitable for large-scale heap leaching.

5. High leaching rate: it can leach the gold ions effectively and can achieve faster with higher recovery rate than using sodium cyanide.

6. Faster recycling: compared with using sodium cyanide, the heaping process is shorter and the recovery is faster.

7. Lower cost: it can reduce costs such as purchasing, transportation, warehousing, storage, usage, safety and environmental protection facilities.

8. Selective adsorption: activated carbon has the ability to selectively adsorb gold in gold and copper in gold leaching solution, which is beneficial to the separation of copper and gold.

9. Easy to use: the production process is consistent with the condition of using sodium cyanide, which makes it easy to use and promote.

10. Easy to transport: it is an ordinary cargo and can be transported by air, sea, road or rail.

1. The product is powdered and granulated and packed in two layers of plastic bags. The inner layer is thick and translucent plastic bag while the outer plastic bag is printed with words. The printed content shall be provided by Party B to Party A with reference to Party A's content, and Party A shall be responsible for printing.

2. The net weight of each bag is 25.00KG±0.20KG, and then every 40 bags (the net weight of leaching reagent is 1 ton) would be fixed on a wooden pallet, then the 40 bags would be entangled with a wrapping film. The packaging of the product should be suitable for loading and unloading into the container, which is suitable for international transportation.

Ingredients: sodium oxide, nitrogen, ammonium, calcium, iron, etc.

Usage: while being used, the non-cyanide gold extraction reagent must be agitated with alkaline water at normal temperature, and then dissolved in a slurry to do gold leaching. In the process of heap leaching, pool leaching and CIP production of oxidized gold ore, the process is as same as the process of using sodium cyanide. The pregnant solution and the lean solution in production can be reused, and the best material in pregnant solution gold leaching is activated carbon. The leaching effect of gold is best when the ambient temperature is above 10 °C. The reagent can be compatible with cyanide gold extraction.

Alkalinity: it generally use lime, caustic soda, etc. to adjust and maintain the ph value to 10 ~ 12. After the raw ore is piled up or into the pool, it should return water to adjust the alkalinity to pH value 11±1.

Dosage: the dosage is about 0.5 to 1.0 parts per thousand (500-1000 g of drug/ton of ore). The property, grade and pH of the ore affect the dosage. The actual dosage can be calculated according to the concentration of the solution.

Dosing method: it can be used after being fully dissolved in water at normal temperature (usually the dissolution in flowing water or after sufficient agitation would be accelerated). Continuously flush the non-cyanide gold extraction reagent into the medicine pool (lean solution pool) or put it into the medicine tank to dissolve. If it is a heap leaching process, dosing and spraying can be carried out simultaneously.

Drug concentration: because the composition and pH of different ores are different, the non-cyanide gold extraction reagent should be dispensed according to the actual ore amount and the optimal concentration of the drug obtained from the experiment. The concentration of the drug can be tested according to the method provided by us.

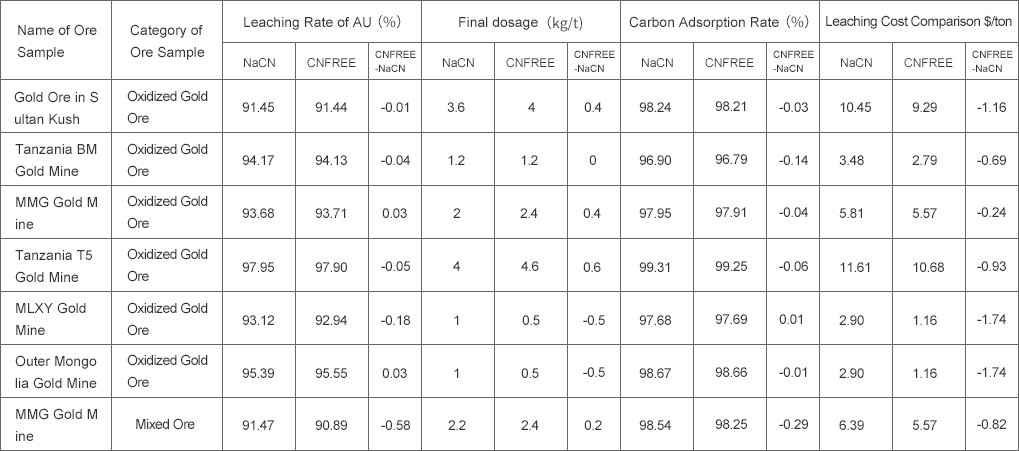

In order to investigate the difference of NaCN leaching reagent and CNFREE leaching reagent in the leaching effect on gold ore, we choose six kinds of gold ore samples which are oxidized gold ore in Sultan Kush, oxidized gold ore in Tanzania (Busolwa Mining Ltd), oxidized ore and mixed ore of gold mine(ie containing both oxidized ore and primary ore) in Tanzania (MMG GOLD LIMITED), oxidized gold ore gravity separation tailings in Tanzania (T5) for leaching comparison test. With same other cyanide leaching conditions, the research focused on the difference of the leaching agent dosage, leaching rate, gold adsorption rate when using NaCN or CNFREE as the leaching reagent, and also carried out the economic benefit analysis of the comparable projects.

TOP